This machine is specialized for PET recycled round/flat yarn produce. It can used the bottle flakes as material. The fiber is smoothly and straight. It is popular used for broom & brush making.

Machine Details:

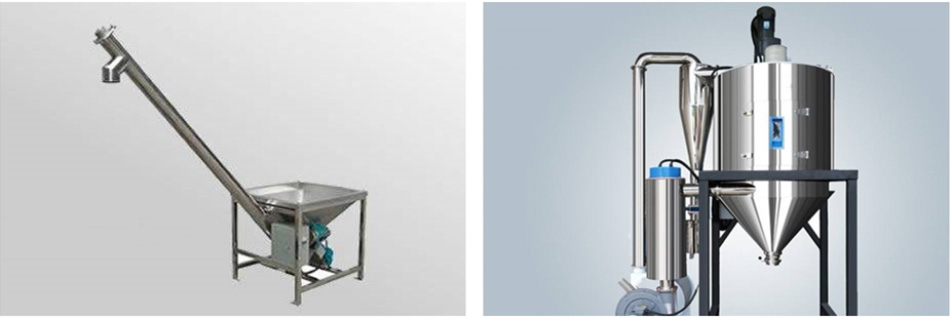

Automatic screw feeder + Drier system:

Flake is not evenly out shape, must adopt screw feeder. The ordinary suction feeder is not work for flakes.

The pet flake must do very good dry, becasue pet mateiral is water sorbing quality. the drier including 2 phase, each phase need enough dry time.

Extruder Head:

Screw adopts Nitriding process, could bear high temperature, more durabile, and good plasticizing quality. Machine with pressure sensor and metering pump to control the f pressure and the flow. It's convenient to change different spinneret size to make different dia of yarn.

Stretch Roller:

SS material is to make the yarn good stretching, steady speed. We have different roller design for different yarn, 5 roller or 7 roller. with rubber cover or just stainless steel material. the transmission adop gear type make sure the roller running stable no bounce up and down. roller bounce will lead to yarn thickness no evenly.

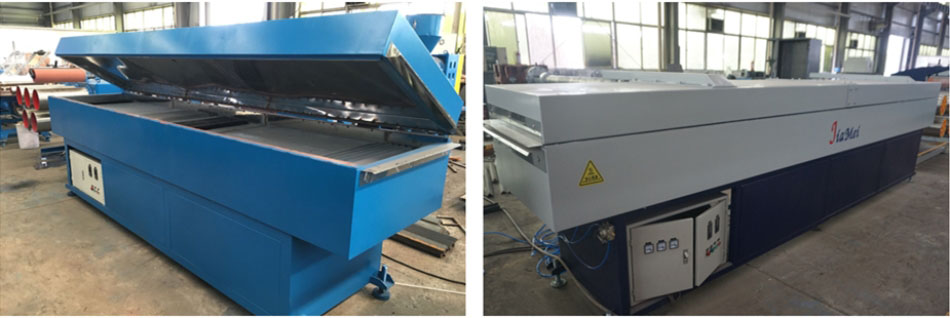

Heating oven:

The heating oven use thicker material, has very good thermal insulation performance and keep inside temperature stable.

Winder:

Winder has separate motor to control each winding head, for monofilament, there exist several kinds of winding type. The winder have Oliver shape, H bobbin type, star type etch for different yarn usage, motor very durable.

Technical Parameter:

| Machine Model | Screw Diameter | Machine Capacity | Main Power | Winder Numbers |

| JM65 | 65mm | 1200kg/24hr | 90kw | According to the yarn diameter and capacity |

| JM70 | 70mm | 1800kg/24hr | 100kw | |

| JM80 | 80mm | 2500kg/24hr | 120kw | |

| JM90 | 90mm | 3000kg/24hr | 140kw |

Production Process:

raw material (PET recycled) --> automatic loading hopper+ dryer +dryer --> extrusion screw --> filter system --> cooling water tank --> No.1 drawing roller --> hot water tank --> No.2 drawing roller --> ( hot air oven+ No.3 drawing roller) --> auto winder( for different kinds of bobbin size and yarn size request)

Recycled PET Monofilament yarn Application:

PET recycled yarn is widely used for making brush, broom, rope , net, etc.

FAQ:

1. What's the model you have ?

Here are 65mm, 70mm, 80mm, 90mm, 100mm, 110mm for your choice.

2. Whats' the yarn size can do ?

The minimun we can do 0.06mm, and for some products like brush , we can do 2-3mm.

3. What's the winding type you have ?

For pp and hdpe , generally is olive type, 3-5kg, and base on clients request, we can use nylon bobbin, paper bobbin, and big frame for brush / broom yarn winding.

Our Service:

Pre-Sales Service

* Inquiry and consulting support.

* Sample testing support.

* View our Factory.

* With online device, our team is 24hr at your service.

After-Sales Service

* After machine delivery, we will arrange engineer and skilled worker come to customer's factory help with machine start running and training.

* We will provide the technical know-how for your operation smooth transition and support for installing, debugging, operation of the machine, it will indicate you how to use this machine well.

* Provide free upgrades and maintenance for software system within warranty period.

* Provide preferential lifetime maintenance of all equipment, spare parts are charged according to the prevailing market price after warranty period.

* With online device, our team is 24hr at your service.

Copyright © Jiamei Machinery Technology Co., Ltd. All Rights Reserved | Sitemap